PP/HDPE Woven Fabric Rolls

PP/HDPE Woven Fabric Rolls

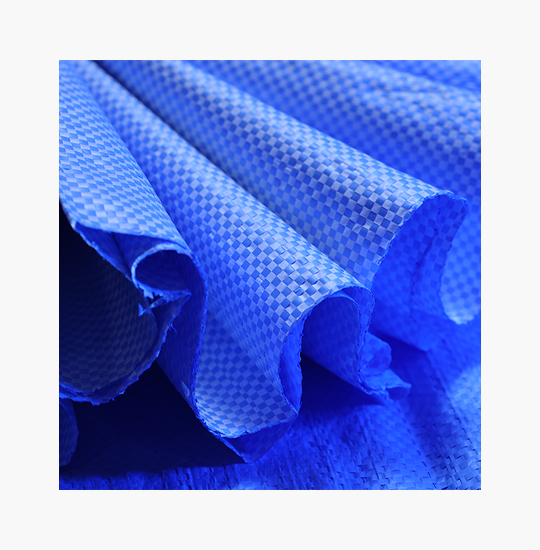

Tubular fabric, woven from PP/HDPE tapes, is renowned for its strength and versatility, making it a popular choice worldwide. Discover our customized products and experience the excellence that distinguishes us.

Features

APPLICATION

PP/HDPE woven fabric is widely used across various sectors, including the manufacturing of sacks, bags, and FIBC jumbo bags, as well as for tarpaulin production, paper roll and textile product coverings, baling and wrapping, pipe covering, landfill capping, steel wrapping, truck covering, roofing underlay, crop protection during storage and transportation, pest and weather protection for crops, and wrapping and covering of construction equipment and tools. Its versatility makes it valuable for numerous commercial, industrial, and manufacturing applications.

BENEFITS

PP/HDPE woven fabric provides easy customization in size, color, and printing, allowing businesses to create branded packaging solutions. Its cost-effectiveness compared to other materials makes it an economical choice for various applications. Lightweight and manageable, it is simple to transport and store, while its durability withstands rough handling and harsh weather conditions. Additionally, its breathability and protective qualities make it particularly beneficial in agricultural settings, where plants need both ventilation and protection.

Technical Specification

| WIDTH (CIRCULAR) | 30 CM TO 242 CM (12 TO 95 INCH) |

|---|---|

| WIDTH (FLAT) | 30 CM TO 400 CM (12 TO 157 INCH) |

| ROLL LENGTH IN METER | AS PER CUSTOMER REQUIREMENT |

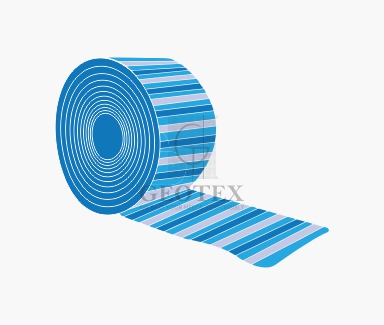

| FABRIC COLOR | MILKY WHITE OR AS PER CUSTOMER REQUIREMENT |

| FABRIC METERIAL | PP / HDPE |

| FABRIC TYPE | TUBULAR / CIRCULAR / FLAT |

| GSM | 40 GSM TO 160 GSM |

| MESH | 8 X 8 TO 16 X 16 PER SQUARE INCH (STANDRAD 10 X 10) OR AS PER CUSTOMER REQUIREMENT |

| LAMINATION (ON CIRCULAR FABRIC) | TWO SIDE / ONE SIDE LAMINATION (OUT SIDE OF THE FABRIC) |

| LAMINATION (ON FLAT FABRIC) | TWO SIDE / ONE LAMINATION |

| LAMINATION METERIAL | GLOSSY / MATTE |

| PRINTING | AS PER CUSTOMER REQUIREMENT (UPTO 6 COLOR) |

| UV STABILIZATION | AS PER CUSTOMER REQUIREMENT |

| GUSSET | AS PER CUSTOMER REQUIREMENT (5 CM TO 25 CM) |

| AIR VENTILATION/PREFORATION | AS PER CUSTOMER REQUIREMENT |

| SIDE SEALING (IN FLAT FABRIC) | HEAT SEAL / COLD SEAL / ULTRASONIC SEAL |

| PAPER CORE ID | 40 MM, 76 MM, 100 MM OR AS PER CUSTOMER REQUIREMENT |

| TYPE OF PACKING | 2000 METER PER ROLL OR AS PER CUSTOMER REQUIREMENT |

PP woven fabric rolls manufacturer | PP woven fabric rolls Surat | PP woven fabric rolls Gujarat | PP woven fabric rolls India | HDPE woven fabric suppliers India | Local woven fabric rolls manufacturer | Durable packaging fabric Surat | Eco-friendly PP fabric India | Wholesale woven fabric Surat | Custom woven fabric rolls India | Industrial packaging fabric Surat | Heavy-duty woven rolls Surat | Woven fabric distributors near me